The ISO 11135 defines the requirements associated to the development, validation and routine control of the process of sterilization with ethylene oxide.

The sterilization of medical device products with ethylene oxide or mixture of gases containing variable amount of ethylene oxide is one of the most important methods for sterilization. We have already been talking on different occasions about the requirements for sterile products, for example in the article related to ISO 11137 related to gamma sterilization or to ISO 11167, linked to the packaging requirements for terminally sterilised medical devices.

We have been extensively discussing about process and design validation, such as biocompatibility, clean room validation, packaging validation and much more. In this article we will go through the main requirements associated to ISO 11135, including the steps to be performed for the validation of the ethylene oxide sterilization as well as qualification of the equipment linked to this process.

QMS Requirements as per ISO 11135

In order to properly keep under control the sterilization process, it is necessary to address specific requirements within the quality management system.

First of all, it is important to have dedicated procedure for the design, validation, routine control and product release for the sterilization process; it is also necessary that all the documentation related to the ethylene oxide sterilization process is approved by personnel with a specific level of training and experience. `

Management responsibilities are also essential. It is necessary that authorities and responsibilities in relation to the sterilization process are properly defined and that dedicated contract agreement (quality agreement) are up and running in case sterilization activities are performed by external parties.

In a context of product realisation, the ISO 11135 requires the presence of a dedicated procedure purchasing, identification and traceability; the standard procedure aligned with the requirements of ISO 13485 would be sufficient. Moreover, Ian adequate management of the equipment in terms of calibration and maintenance is essential to ensure to have a reliable sterilisation process that can ensure quality safety and efficacy of the sterilization process.

Last point, an efficient method for the management of CAPA and non-conformities is needed, as it is essential in order to manage the deviations in the sterilization process and implement appropriate corrections.

Validation of Sterilization Process according to ISO 11135

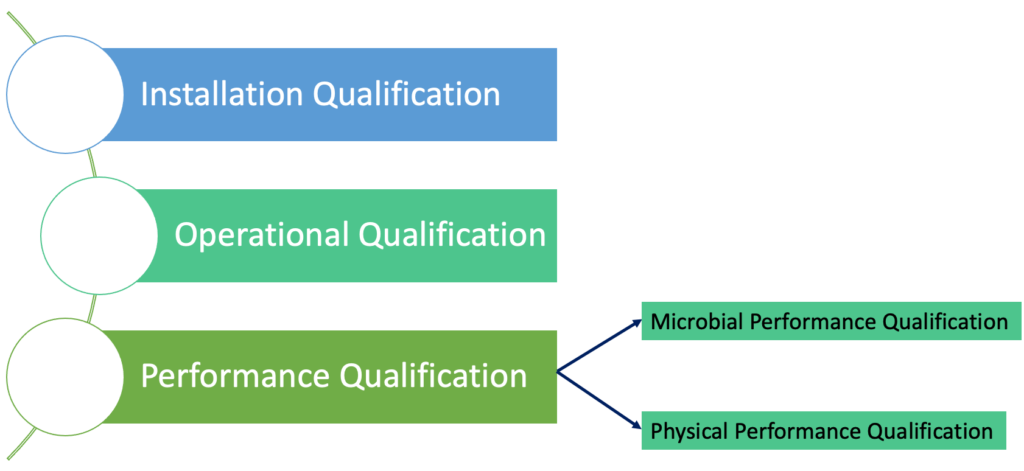

The validation activities of the ethylene oxide sterilization process follow the standard approach based on the so-called IQ/OQ/PQ, meaning Installation Qualification, Operational Qualification and Performance Qualification. In this section we will go through the main requirements for validation activities according to ISO 11135.

Installation Qualification

In the context of Installation Qualification, it is necessary to ensure that sterilisation’s equipment is compliant with their related specification at the location where the equipment is used. All the specifications related to the used equipment need to be established and documented

Specific user manual detailing the related procedures for the main activities to be performed with the equipment such as, for example, step by step instructions manual, a list of error and actions to be taken to resolve it, instructions for maintenance and calibration and information on contact and technical support.

It is also necessary, always in the framework of Installation Qualification, to have detail specifications for any type of customer services and for all the preventive maintenance and actions to be performed on the equipment at the installation site.

Moreover, instructions concerning any actions to be performed in relation to the health care and safety of the personnel working with the specific equipment.

-

Design Control Package€169,00

Design Control Package€169,00 -

Design Control Procedure€64,00

Design Control Procedure€64,00

Operational Qualification

The goal of the operational qualification is to establish specific tolerance for the process and ensure that the installed equipment is able to performed the specified process within that tolerances.

Attention should also be paid to the calibration of the equipment to ensure that, in this phase of the validation effort, all the calibration and maintenance is performed.

Performance Qualification

Based on the ISO 11135, performance qualification (PQ) for the process of sterilization with ethylene oxide consists of two different parts:

- Microbial Performance Qualification (MPQ)

- Physical Performance Qualification (PPQ)

The microbial performance qualification is aiming at finding the appropriate minimum process parameters in order to ensure product bioburden is killed. More specifically, the microbial performance qualification uses half sterilization cycle (meaning a cycle lasting half of a normal time in the sterilization chamber) with the goal to demonstrate a sterility assurance level (SAL) equal to 10-6. This test is typically performed in at least three cycles and the requirement is to have a sterile product in all the cycles.

This method is called the “overkilled” methodology, because during standard operations the full cycle will then be used, which indeed is considered an overkill.

The physical performance qualification (PPQ) typically consists of three full cycles and measurement of EO residuals in accordance with ISO 10993-7:2008.

Moreover, it is necessary to show, in the context of a PPQ, that after the product has been sterilized, it remains fully functional with no specific effects on quality, safety and functionality of the device.

Sometimes in the context of the PPQ it is possible to add a second cycle to confirm that the product can be sterilized a second time, with no specific impact on the safety and the performance of the product. This allows the validate a second sterilization cycle that can be used in case a first cycle went wrong, without the need for additional process validation activities.

It is very important to highlight that the Performance Qualifation phase shall be repreated every time there is a change in the product, packaging, loading con- figuration, equipment, process parameters.

A deep dive into Microbiological Performance Qualification (MPQ) according to ISO 11135

One of the critical aspect of the ethylene oxide sterilization process for the MPQ phase is the collection of evidences that the cycle is indeed killing all the microorganisms, ensuring thus an adequate assurance of sterility. In fact, during the MPQ, the so called “Process Challenge Devices” (PCD’s) are placed inside and outside the load. the PCD’s contains what is usually refer as biological indicators, basically a strip with a million bacteria, of a species which is relatively resistant against ethylene oxide gas.

The challenge during the MPQ phase is to demonstrate that the biological indicator’s in the Internal PCD are killed more easily than the BI’s in the External PCD. This is checked during a separate “sub-lethal” cycle in which the sterilization cycle is too short to kill all of the million bacteria of the biological indicator’s. When the percentage of kill is larger for the Internal PCD’s than for the External PCD’s, the monitoring of routine production cycles can be performed with External PCD’s only.

Subscribe to 4EasyReg Newsletter

4EasyReg is an online platform dedicated to Regulatory matters within the medical device, information security and AI-Based business.

We offer a wide range of documentation kits to support your compliance efforts towards a wide range of standards and regulations, such as ISO 13485, EU MDR, ISO 27001, ISO 42001 and much more. . Specifically, in our webshop you will find:

- ISO 13485 Documentation / Compliance Kit

- EU MDR Documentation Kit

- MDSAP Documentation Kit

- ISO 27001 Documentation / Compliance Kit

- ISO 42001 Documentation / Compliance Kit

- FDA Cybersecurity Documentation

Within our sister platform QualityMedDev Academy, a wide range of online & self-paced training courses is available, such as for example:

- Complaint Handling and Vigilance Reporting

- Artificial Intelligence in Medical Device. Regulatory Requirements

- Unique Device Identification (UDI) Requirements according to EU MDR

- Clinical Evaluation Process According to EU MDR

- Medical Device SW Verification & Validation

- Risk Management for Medical Devices

- Usability Evaluation for Medical Devices

As one of the leading online platforms in the medical device sector, 4EasyReg offers extensive support for regulatory compliance. Our services cover a wide range of topics, from EU MDR & IVDR to ISO 13485, encompassing risk management, biocompatibility, usability, software verification and validation, and assistance in preparing technical documentation for MDR compliance.

Do not hesitate to subscribe to our Newsletter!